Home >

News Information >

Qingli News > Qingli | Tank Immersive Heat Exchanger with Heat Transfer Efficiency Up to 95 %

Home >

News Information >

Qingli News > Qingli | Tank Immersive Heat Exchanger with Heat Transfer Efficiency Up to 95 %1.Introduction of plate heat exchanger

Flat plate immersed heat exchanger, an immersed plate heat exchanger placed in the tank, is composed of two special heat transfer wall plates. The fluid movement channel is formed between the heat transfer plates, and the heat exchange is carried out by the inter-wall heat transfer mode. It is an ideal equipment for liquid-liquid and liquid-vapor heat exchange. It has high heat transfer efficiency, low heat loss, easy installation and cleaning, corrosion resistance, heat transfer efficiency up to 95 %, can be used for chemical surface treatment, coating engineering, spray pickling and other fields.

2. Technical parameters

The overall thermal structure of the immersed heat exchanger is based on the principle of corrugated expansion heat transfer of rectangular plates and shells. The surface coefficient of the heat transfer plate effectively improves the heat transfer factor in the fluid motion-fluid turbulence rate, reduces the thermal resistance and temperature gradient of the fluid boundary layer, and promotes the fluid to the whole plane. Transfer, thereby enhancing heat transfer efficiency.

3. Installation instructions

Plate unit structure, simple installation, series parallel combination, installation diagram is as follows :

Installation diagram of example

4. Specification types

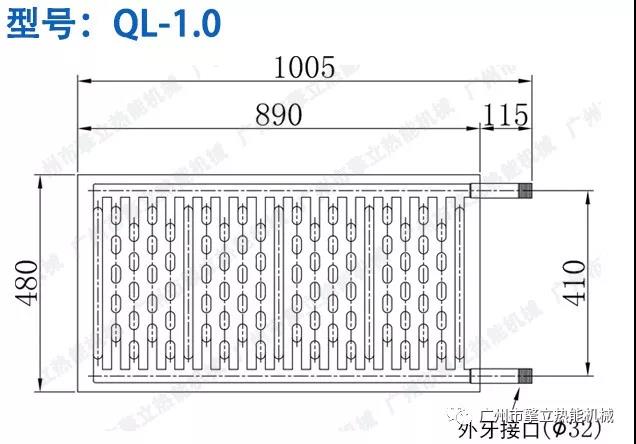

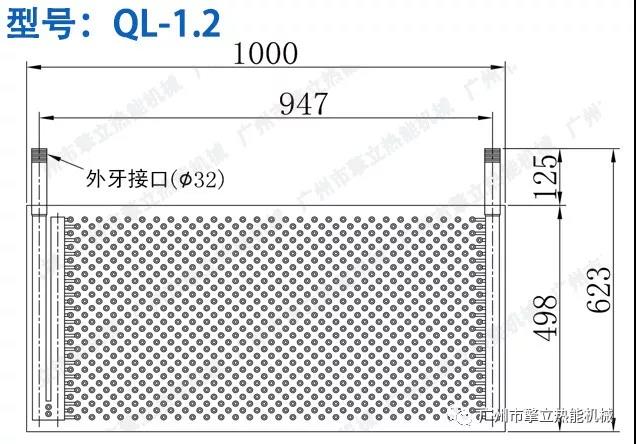

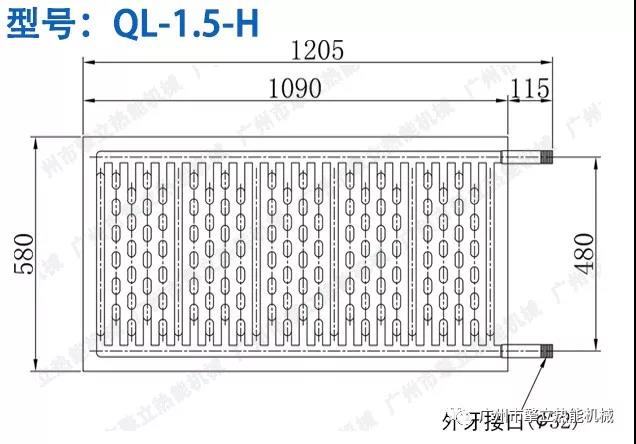

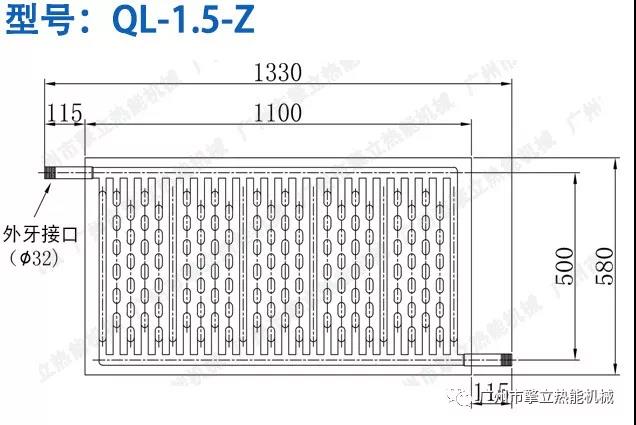

Immersive heat exchanger, made of stainless steel SUS304, SUS316L, working temperature : -20 ~ 280 °C, design pressure of 0.6Mpa, the specific model specifications and parameters are as follows :